China 2019 ISO/Ce Dem/Del Speed Adjustable Quantitative Weigh Feeder for Cement/Gypsum/Feed

20+ Apron Feeder Parts BarimaFaluin

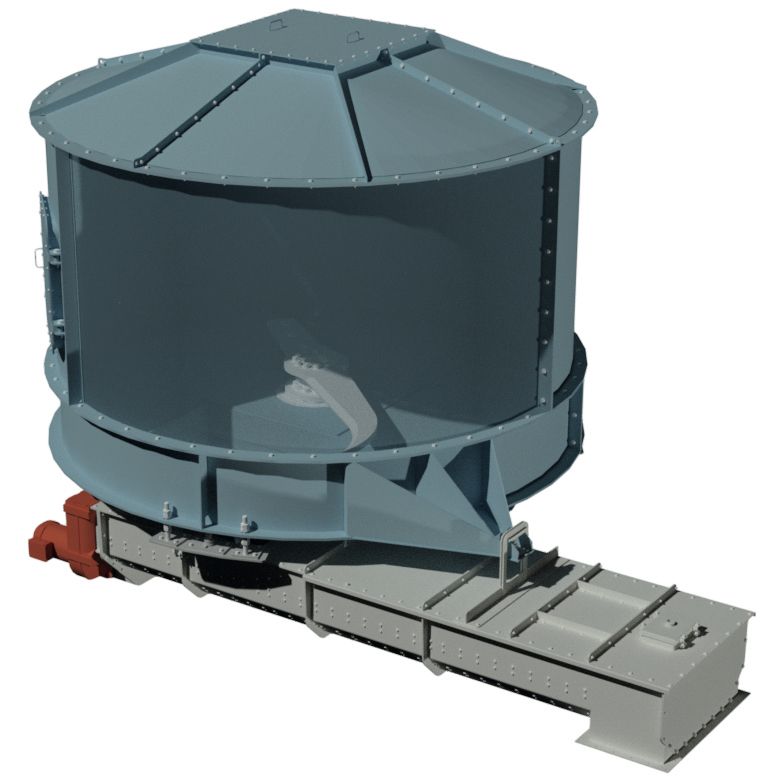

Rotary weigh feeder. The ROTAWEIGH is a rotary weigh feeder. The rotary weigh feeder is supplied from the top of the ROTAWEIGH via a regulated valve, directly from a. silo, a surge tank or a pre-installation. A control valve is an actuator that combines a valve body with electric or even pneumatic actuation in industrial applications.

weigh feeder in cement plant..... YouTube

In the course of modernising this cement plant a traditional belt weighfeeder with rubber belt (see upper picture) was replaced by a rotor weigh-feeder Pfister® TRW. While the customer had to replace the belt of the old installation regularly, with rotor weighfeeder Pfister® TRW wear and maintenance were reduced drastically.

Weigh Feeders J McCoy Equipment

cement industry. Conveyor belt scales and weigh feeders are important equipment in cement plants. Belt scales and weigh feeders are frequently used to help control inventory, maximise raw materials usage and aid in producing a consistent product. Correct installation and maintenance are required to achieve this.

HASLER Group Cement process

Weigh feeder is a closed-loop control system, which controls the flow of material very accurately using controller and different instruments. This system accepts an external command from process computers like SCADA, HMI, DCS etc. This type of weigh feeder used in industries like Steel Plant, Cement Plant, Fertilizer and Chemical industries.

Belt Weighing Feeder Supplier, Raw Materials PLC System for Cement Mill

The use of world leading brand components guarantees the reliability of the belt weigh feeders. Applications. Dosing of granular products in large flows rates.. Application for dosing of fly ash, crude flour for production of clinker, cement, coal, feldspar, clays, all types of flours and any product with little slope and very small.

Cement weigh hoppers

Weigh belt feeder for granular materials. The material passing through the feeder hopper of the belt feeder is extracted from the storage silo by the belt and then conveyed to the weighing bridge. The flow rate of the Gravit is calculated according to the speed of the belt and the load measured when it reaches the weigh bridge.

China 2019 ISO/Ce Dem/Del Speed Adjustable Quantitative Weigh Feeder for Cement/Gypsum/Feed

Designers can offer accurate weighing systems to maintain the set rate of material transfer, which can simplify the task of process engineers. This is effected by the closed loop control of the feeding mechanism using weighing. The kind of set-up designed for this purpose is known as Weigh Feeder. Weigh Feeder is a closed loop control system in.

Stainless Steel Frame Belt/ Weigh Feeder for Cement/Food/Coal Industry China Reciprocating

The global cement market produced 5.17 billion tons of cement in 2020 and the market is expected to grow by 3.3% each year from 2021 to 2026. This means 6.08 billion tons of cement by 2026. Weighbelt feeders are essential to the production of every ton of cement. The more cement is being produced, the more important it is to have accurate and.

Rotor Weigh Feeder For Cement Industry

The PFISTER® Smart Linear Feeder can help you achieve the control you need. Learn more. Every part of a manufacturing line relies on accuracy, consistency and reliability to deliver optimum productivity. That's why we use continuous gravimetric dosing in PFISTER® belt weighfeeders. Accurate dosing on a robust linear system available in a.

Antares Weighing Weighing company Weigh Bridges Weight Indicators Pit less Weigh Bridge

Weighing Feeder. A weigh feeder is a crucial component of many industrial processes, particularly in industries that involve the handling and processing of bulk materials such as mining, cement, food, and pharmaceuticals. It is a type of weighing system designed to accurately measure and control the flow of material, ensuring that a consistent.

Weigh belt feeder for cement, fertilizers, steel, auminium plant

Weighfeeder signals and information, such as Weight, Speed, Belt tracking, Belt index are directly connected to the SCM-3 controller. The SCM controller calculates the actual flowrate, totalizes the conveyed material and generates the control signal for the variable speed drive. Detailed alarm informations are obtained via the display (SDU).

7 Properties of a Reliable Weighbelt Feeder for Cement Production Advancing Mining

Weigh Belt Feeders for the Cement Industry Web Tech AutoWeigh have been supplying weigh belt feeders to the cement industry for over 25 years. Handling products such as clinker, cement, gypsum and limestone, we have a range of standard models suitable for nearly any application. We have also modified the standard designs to suit existing plant

Beumer Group develops screw weigh feeders for precise and controlled feeding of alternative

Cement production weigh feeders are expected to perform very accurately and repeatably, while constantly enduring the harsh plant environment. Several fundamental practices maximize the accuracy performance when dynamically feeding bulk materials such as limestone or clinker. The following "weighing basics" allow for extremely

Dosage, Agitation, Filtration, Malaxage Cement process

The PFISTER® DRW rotor weighfeeder is designed for dosing pulverised fuel, such as lignite, coal dust, petcoke or oil shale. But all PFISTER rotor weighfeeders use the same weighing and dosing principle. Material is extracted from the storage silo and transported in the rotor chambers from the inlet to the outlet.

ISO Approved Stainless Steel Frame Belt/ Weigh Feeder for Cement/Food/Coal Industry China

In cement and mineral processing, weigh-feeders can be used to provide rate control for blending raw materials or additives. DESIGN. Durable and almost maintenance free, McCOY WW300 is custom engineered to meet the application. It is specially designed for heavy-duty industrial and harsh applications. The design eliminates material build-up to.

FB Hot Sale Belt Weigh Feeder for Cement Plant(id9225707) Product details View FB Hot Sale

cement industry, matching kiln through-puts of up to 12,000-13,000 tpd. We offer an extensive selection of stacker and reclaimer systems to meet. and fed to the mill by weigh feeders. Direct mode: If the materials are diffi-cult to handle, it may be an advantage to avoid the intermediate bin between the reclaimer and the mill. This is possi-