TECO Motor 3HP 4Pole 380V fnengineering

TECO TECO Low Voltage 3 Phase Induction Motors

If the motor has only three leads, two must be connected together to form one circuit through the winding. In this case, one phase will carry the full applied current and each of the others, one-half each. If the motor has six leads (3 mains and 3 neutrals), the three phases should be connected into one series circuit.

TECO TECO Low Voltage 3 Phase Induction Motors

0.18kW to 185kW. Totally Enclosed Fan Cooled (IC411) MAX-E2, motor types AEHB & AEHD, meet AS1359.5 Minimum Efficiency Performance Standard, table B2. MAX-E3, motor type AEMB, meet AS1359.5 *Minimum High Efficiency Performance Standard, table B3 (some motors are MAX-E3 as standard) 380~415 Volts 3 Phase 50 Hz (other supplies on request) Highest.

TECO TECO Low Voltage 3 Phase Induction Motors

If you are looking for a comprehensive motor catalogue, you can download the TECO Te3 Catalogue PDF from this link. It contains detailed specifications, dimensions, performance curves and wiring diagrams of the Te3 Low Voltage 3 Phase Induction Motors, which are designed for high efficiency, reliability and durability. Whether you need a motor for general purpose, severe duty, smoke spill or.

TECO Middle East (TME) is the first electrical medium and high voltage induction motors

Method (1): After installing the coupling, use a grinding wheel to remove the redundant key (hatch area). Method (2): Before installing the coupling, calculate the different length between coupling hub and shaft key, then cut the half of this different value (hatch area) to achieve approximate-balance condition. Redundant.

Teco Induction Motor ( Copper Wire ) Three Phase, 220V, 60Hz.

TECO Westinghouse Motor Company comprises the experience of Westinghouse, a leader in the motor industry since 1888 and TECO, a multinational conglomerate with over 50 years of motor experience. TECO Singapore itself was established in 1972 and has also set-up subsidiaries in Thailand, Malaysia, Indonesia, Vietnam and India.

TECO Motor 3HP 4Pole 380V fnengineering

3.1 Site and environment for motor installation. 3.1.1. Standard environment and site conditions for the installation of motors are usually set as follows: Ambient temperature:-20 ~ +40 °C. Humidity:Relative humidity shall be below 95%RH for totally-enclosed types, and below 80%RH for semi-enclosed types.

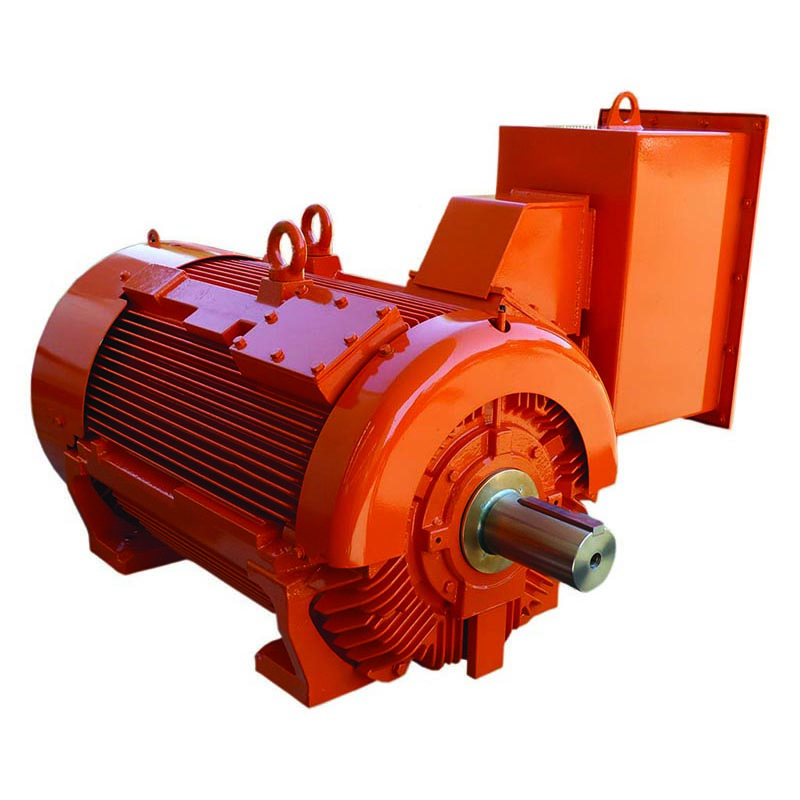

Three Phase Electric Motor 110kW 4P (1485rpm) 415v B35 Foot/Flange Mounted TCI315S4 IP55 Cast

Safe running speed for the squirrel-cage induction motors. Unless otherwise the name plate specifies, all the squirrel-cage, 3 phase, induction motors lower than 1000V and smaller than 315 Frame Size can safely run continuously at the speed in the table below. The safe Max. r.p.m. for the squirrel-cage, 3 phase induction motors of 1000V or lower.

Teco 3 Phase Induction Motor Wiring Diagram Wiring Diagram

MOTOR RANGE FROM TECO TECO' s position as a world leader in the design and manufactuing of large induction motors is secured by an unfailing commitment to engineering excellence and technological innovation. For a half a century TECO motors have been recognized as industry leaders in dependabili ty and quali y. TECO MOTOR PRODUCTS

Teco 3 Phase Induction Motor Wiring Diagram Wiring Diagram

Key Features. Metric frame motor to AS1359, IEC60034 frame allocation (some motors also to AS/BS frame allocations) 0.55kW to 500kW. Totally Enclosed Fan Cooled (IC411) Meets IEC60034-30-1 (IE3) Efficiency. 380~415 Volts 3 Phase 50 Hz (other supplies on request) Class F insulation with a Class B temperature rise. Continuous rated, duty type S1.

TECO Induction Motor Industrial Fan and Blower Philippines

Palo Alto, CA Service Company* $1 - 4.9 Mil 1966 10-49. Electric motor repair and rewinding services. Equipped with automatic dip, bake, and temperature control burn ovens. Capable of rewinding AC and DC motors up to 1000 hp in capacity. Also a distributor of electric motors, pumps, and electric motor parts.

MOTOR TECO smartdrive

Standard 3-Phase Induction Motors TEAAC High Voltage Crown Type Motors Output 400~15,000HP (298 ~ 11,200 KW) Pole (Speed) 2~ 12 Voltage 2200 ~ 6900V Frequency (Hz) 50, 60 Frame Size 355 ~900 Protection Enclosure IP 55 Design Standards: IEC, BS, NEMA, CNS Environment: non-hazardous. Type Code: AEHA / AEHVTOP. Standard 3-Phase Induction Motors

Jual dinamo motor teco 3 kw 4 hp 4 pole b3 di lapak pt genta jaya abadi samsul_dlp

(a) Protect the motor in accordance with measures stated in 2.3. (b) Insulation resistance test should be performed as stated in 2.4. 2.6 Bearing protection (a) If the motor has been provided with a shaft shipping brace to prevent shaft movement during transit, it must be removed before operating the motor. It is very important that

TECO Electric Motors

If you are looking for a comprehensive manual for the TECO TE3 series of three phase induction motors, you can download it from this link. The manual covers the installation, operation, maintenance and troubleshooting of the TE3 motors, as well as the technical specifications and dimensions. The manual is compatible with the TECO warranty and safety standards.

Teco induction motor AC 3phase / CV.CANDI MAKMUR TEKNIK

TECO 3-Phase Electric Motors. Alloy Frame. * Metric frame motor to AS1359. * 0.09kW to 18.5kW. * Totally Enclosed Fan Cooled (IC411) * Meets AS1359.5 Minimum Efficiency Performance Standard, table B2. * 380~415 Volts 3 Phase 50 Hz (other supplies on request) * Class F insulation with a Class B temperature rise. * Continuous rated, duty type S1.

CMG PPA315L4 3PHASE MOTOR 1485RPM 415V 200KW eBay

The specific curves of the LC electric motor reduce the temperature and noise during operation. The design of LC electric motors is maximally optimized for perfect operation with the lowest possible vibrations and high overload capacity. LC electric motors are designed so that they can be switched on directly or via a frequency converter.

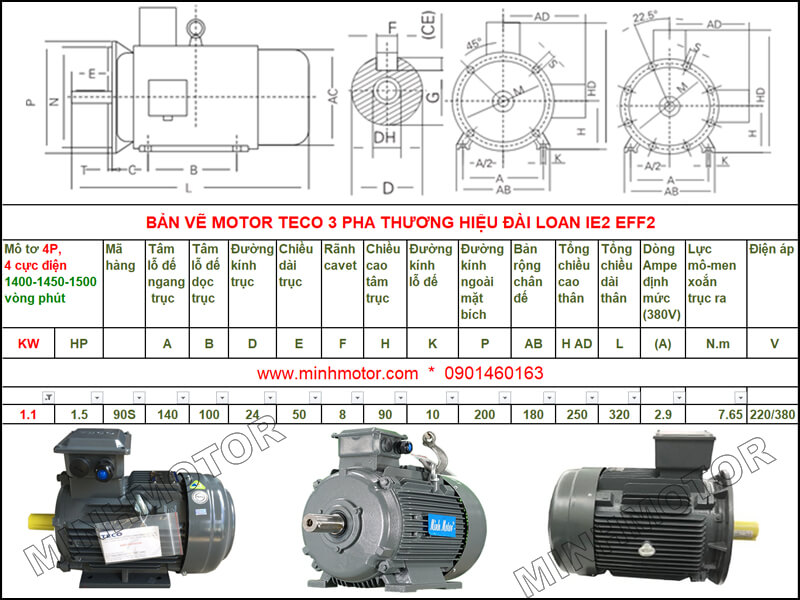

Motor Điện Teco 3 Pha 1.5HP 1.1Kw Động Cơ Điện Teco 1.1Kw 1.5HP

Maximum ambient temperature is 40°C. Other insulation Classes are available on request. Supply and Operation Conditions: Electric Supply: Standard stock available is 220-240/380-415V/50HZ for 3HP and below 380-415/660-720V/50HZ for 4HP and above. Other voltages such as 200V, 346V, 440V up to 690V and 60HZ.