Double Deep Pallet Racking Teepee Warehouse Solutions

Double Deep Pallet Racking System Pallet Racking Australia

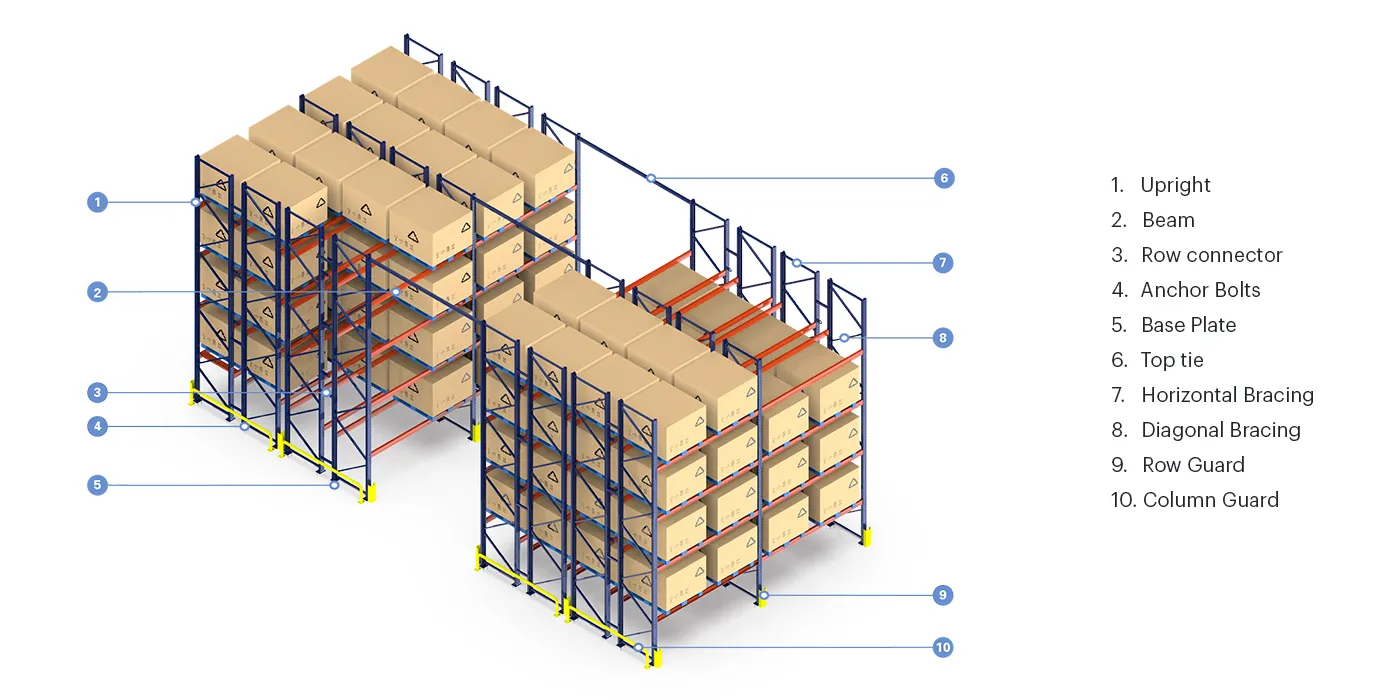

Double Deep Pallet Racking is designed to store two pallets deep, which consist of two standard Selective Racks set up back-to-back. This system has to be used with double deep reach truck with deal pantograph or extension for attachment. Although with increase storage capacity, only 50% of pallets can be immediately accessible.

Live Pallet Racking Pallet Flow Racks System

The Leading Source for Warehouse Racking Systems, Supplies & Services. Call Us Today! Over 34 Years Experience in Inspections, Installations & Repairs.

Godrej Intralogistics, Storage Solution DoubleDeepPalletracking

Double Deep Pallet Racking is a storage system that is halfway between adjustable pallet racking systems and compact storage systems. REQUEST BUDGET In double deep pallet racking, the unit loads are stored mechanically by forklifts that move along the aisles arranged in parallel to the racking systems. Description

Double Deep Pallet Racking System Pallet Racking Australia

Double Deep Racking is perfect for industries that require heightened storage density, especially when you have lift trucks with extended reach capabilities. Efficient Space Utilization By eliminating aisles, this system boosts your storage space utilization by more than 50%.

Double Deep Pallet Racking For Efficient Storage HEDA lupon.gov.ph

Double Deep Pallet Racking. When compared to Single Deep Selective Pallet Racking, Double Deep Pallet Racking enhances warehouse density by up to 40% by allowing two pallets to be placed i.e., One behind the other to offer 50% selectivity. It is a versatile and efficient racking solution with a good balance between pallet selectivity and pallet.

.jpg)

Double Deep Pallet Racking Storage Solutions In Dubai UAE

DOUBLE DEEP RACK STORES PALLETS DEEPLY INTO THE RACKING SYSTEM, HELPS INCREASING GOODS STORAGE CAPACITY __ Images of Double Deep Industrial Racking System deployed by HAI MY Company __ Pallet Racking PALLET RACKING SELECTIVE RACK DOUBLE DEEP RACK NARROW AISLE Non - Selective DRIVE-IN PALLET RACKING NON - PALLET Non-Pallet Racking System

Double Deep Racking Engineered Products

Double Deep rack systems are industrial pallet shelving options for warehouse environments that are designed to increase storage capacity while still maintaining a high degree of selectivity. Pallets are stored two deep on a single-sided unit or four deep on double-sided racks. Also available: Double deep pallet support Applications:

Double Deep Pallet Racking System Global Storage & Display

Double deep pallet racking is composed of two standard selective racks set back-to-back to form a double deep pallet storage system. These double-deep racks are typically designed to be set against a wall or connected to another double-deep section in the back. Double deep selective racking provides a last-in, first-out product flow.

Double Deep Pallet Rack Deep Reach Rack Twice the Capacity

The image in this section shows a comparison of standard selective vs. double-deep selective in the same space. Both systems are 5-levels high. You see that the standard selective rack yields 3,000 pallet positions in 15 rows of rack with 8 forklift aisles. The double-deep selective rack yields 3,910 pallet positions in 20 rows of rack with 6.

Standard Double Deep Pallet Racking System

Double Deep Pallet Rack Systems increase productive use of floor space by about 60% to 65%. They offer low initial cost, good density and selectivity. Double deep pallet rack has become a very popular choice in high throughput operations by offering efficient use of available storage space. Features: Fewer aisles Increased storage space

Double Deep Pallet Racking system Pallet rack, Heavy duty racking

This type of racking system offers more storage than selective racking systems. And not only is density greatly increased so are the number of pick faces available while operators still enjoy a low cost-per-pallet. How it Works Racking structure is configured to hold between two and four pallets Can be setup as single- or double-entry […]

DoubleDeep Pallet Racking System

Double Deep Racking, or a Deep Reach Rack, is an easy way to double the density of racking between the aisles. Our specialists can help you with buying, selling, installing and improving your warehouse pallet rack system.

Pallet Racking — Waymarc Racking, Shelving & Industrial Supplies

The double deep pallet racking system is a racking storage system derived from heavy duty pallet racking. Its simple construction and high storage capacity reduce the number of aisles required by storing two or more deep pallets, allowing for higher storage density while still allowing operators to access each storage bay easily and relatively.

Double Deep Pallet Racking System StorePro Solutions

Double-deep maximizes warehousing space by reducing the number of aisles while increasing pallet storage space; however, it should also be noted that these systems require the use of a double-deep reach forklift to access the rack system. Designing a double-deep system for proper forklift integration is vital.

double deep racking system

Double Deep Pallet Rack is the first step towards increasing the density of your storage system, and with a cost per pallet position that is close to selective racking, the density is affordable. With some quality planning and or the assistance of a warehouse management system, most facilities are able to manage a fill rate average close to 85 percent.

Double Deep Pallet Racking System Pallet Racking Australia

Double deep racking uses standard selective racking components to store pallets two deep (or four deep in a double entry rack). Double deep racking maximises storage through increased density compared to Selective racking but with reduced pallet accessibility. Special forklifts with forward reach ability are required to use this storage method.