Jasa Machining Surabaya CV Sari Jaya Mandiri Profesional Berpengalaman

Jasa Machining Fabrikasi PT. Mandiri Aktive Nusantara (MAN Engineering)

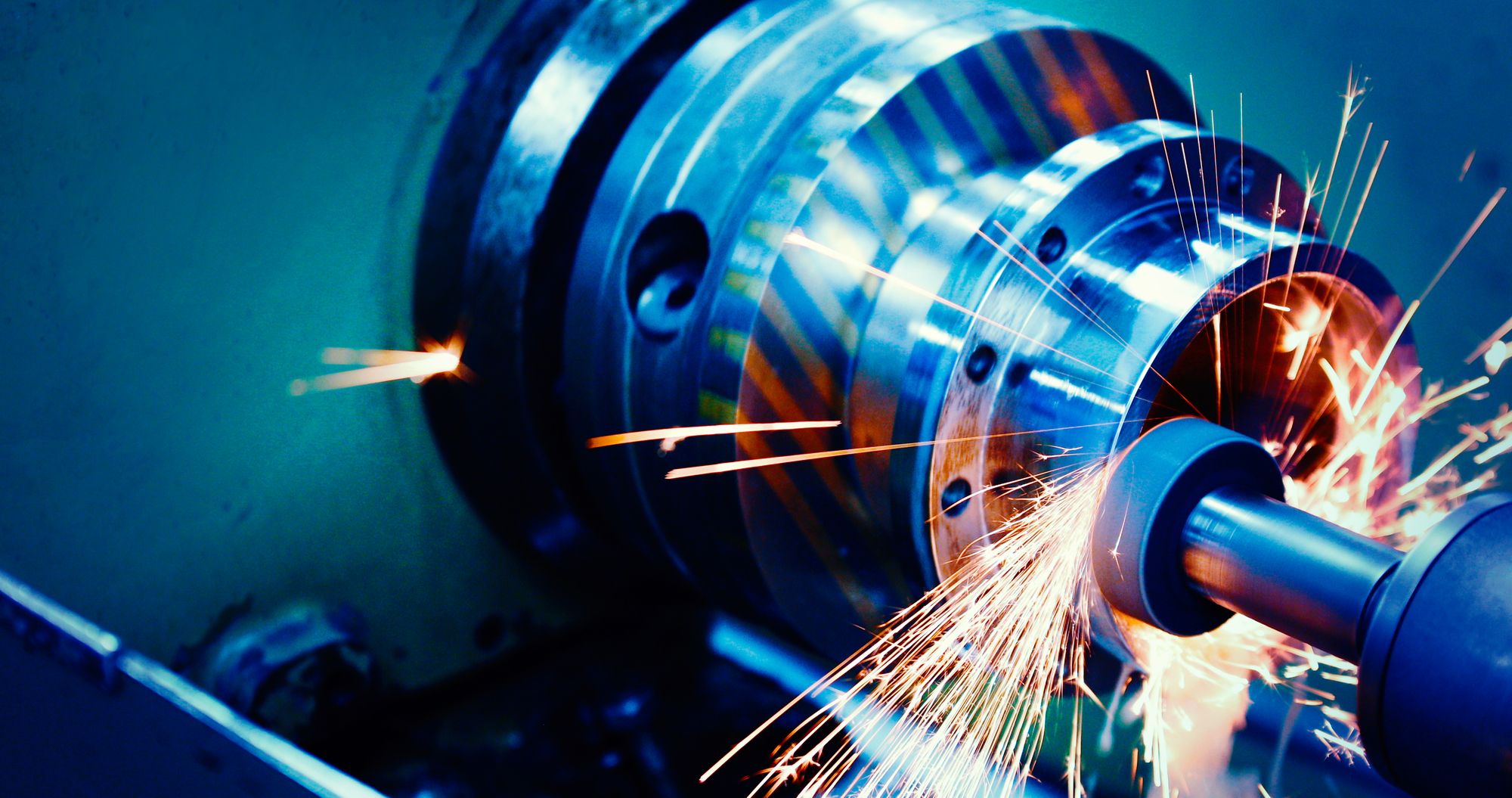

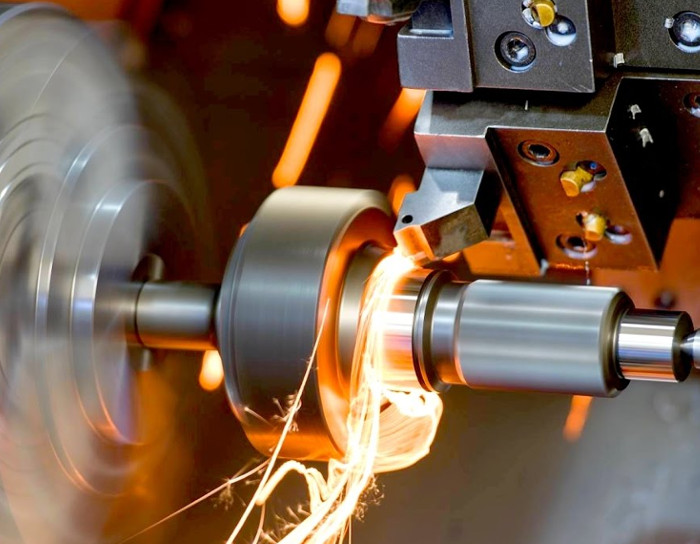

Machining adalah proses manufaktur yang melibatkan penggunaan mesin penuh keahlian untuk membentuk, memotong, atau mengubah bahan mentah menjadi produk akhir dengan presisi dan kualitas tinggi. Dalam industri, machining menjadi tulang punggung yang memungkinkan produksi massal berbagai komponen dan produk yang diperlukan untuk berbagai sektor, mulai dari otomotif hingga teknologi tinggi.

Jasa Machining Surabaya CV Sari Jaya Mandiri Profesional Berpengalaman

JENIS & TIPE ELECTRICAL DISCHARGE MACHINING (EDM) 1. Sinker EDM. Metode Sinker EDM, juga disebut ram EDM, EDM tipe rongga atau EDM volume, terdiri dari elektroda dan benda kerja yang terendam dalam cairan isolasi seperti, biasanya, oli atau, lebih jarang, cairan dielektrik lainnya.

How to process highprecision holes in highspeed? Shank Machining

TRAINING OBJECTIVES. Prevent health and safety risks. Solve mathematical problems related to performing machining tasks on conventional and numerical control machine tools. Interpret technical drawings. Prepare sketches, readings and measurements and perform machining task on conventional machine tools by doing shop work, carrying out turning.

G3 Machining Machining

Proses machining dilakukan dengan langkah-langkah berikut: 1. Persiapan Bahan Kerja. Langkah pertama dalam proses machining adalah persiapan bahan kerja. Bahan kerja dapat berupa logam, plastik, kayu, atau material lainnya yang sesuai dengan kebutuhan. Bahan kerja harus dibentuk menjadi bentuk yang sesuai sebelum dimasukkan ke dalam mesin. 2.

7 Benefits of CNC Machining for Mass Production

TRAINING OBJECTIVES. To understand drawing and solve mathematical problems regarding machining on machine tools, manual and automatical programming just as machining of mass -produced simple and complex pieces. To perform products quality control with measuring tools and related activities before, during and after machining work.

Apa itu Mesin CNC dan CNC Machining

Machining is a manufacturing process whereby a desired shape or part is achieved by the controlled removal of material from a larger piece of raw material by cutting; most often performed with metal material.

Precision Machining Program • SnoIsle TECH Skills Center

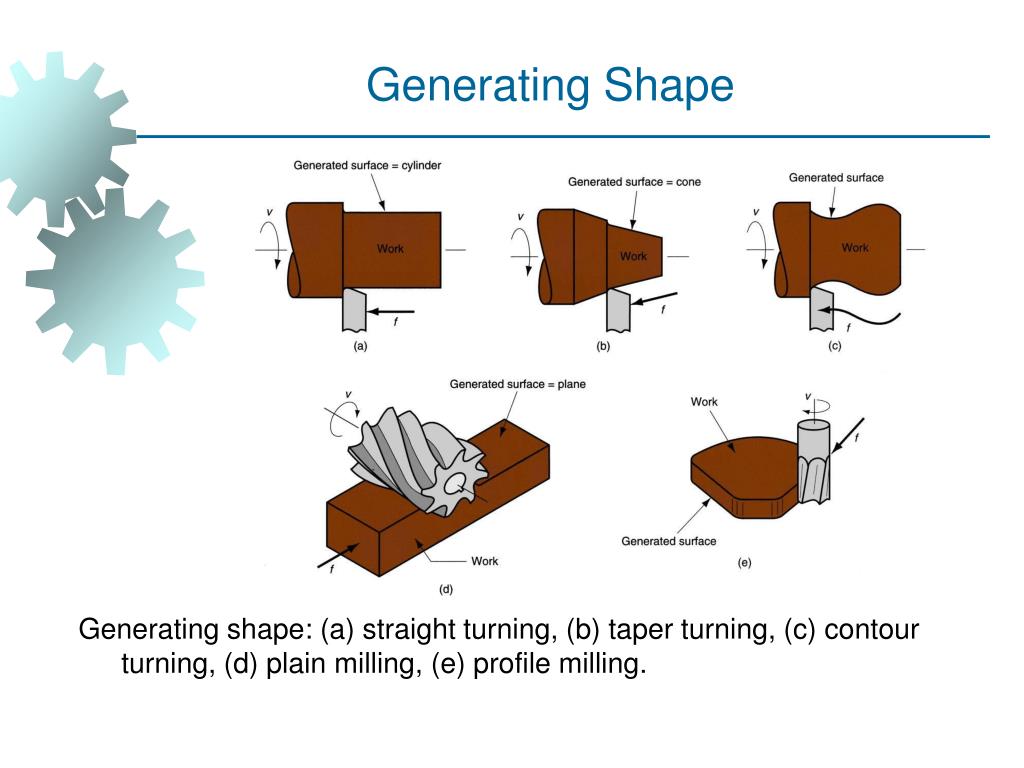

Jul Bagikan ke temanmu!: LinkedIn Facebook Twitter WhatsApp Lagi CNC milling merupakan proses pemesinan yang menggunakan kontrol terkomputerisasi dan memutar alat potong multi-titik untuk secara progresif menghilangkan bahan dari benda kerja dan menghasilkan bagian atau produk yang dirancang khusus.

Milling (machining) Wikipedia

Alat mesin kata benda dan kata kerja untuk mesin (machined, machining) pun akhirnya masuk kedalam kamus besar bahasa Inggris. Sekitar pertengahan abad ke-19, kata-kata terakhir diciptakan sebagai konsep yang mereka gambarkan berevolusi menjadi keberadaan luas. Oleh karena itu, selama Zaman Mesin, pemesinan mengacu pada (apa yang kita sebut.

CNC Machining Easiahome

Machining, Finish. Berikut ini adalah postingan artikel kamus teknis bidang teknik Keinsinyuran yang menjelaskan tentang pembahasan pengertian, definisi, dan arti dari istilah kata machining, finish berdasarkan dari berbagai macam sumber (referensi) terkait, relevan, dan terpercaya yang sudah Kami rangkum.

PPT Machining Family of Material Removal Processes PowerPoint

CAD model and CNC machined part. Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including.

Steel Machining and Machining Process Yena Engineering

Ultrasonic machining. Ultrasonic machining is a subtractive manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The tool travels vertically or orthogonal to the surface of the part at amplitudes.

Precision Machining

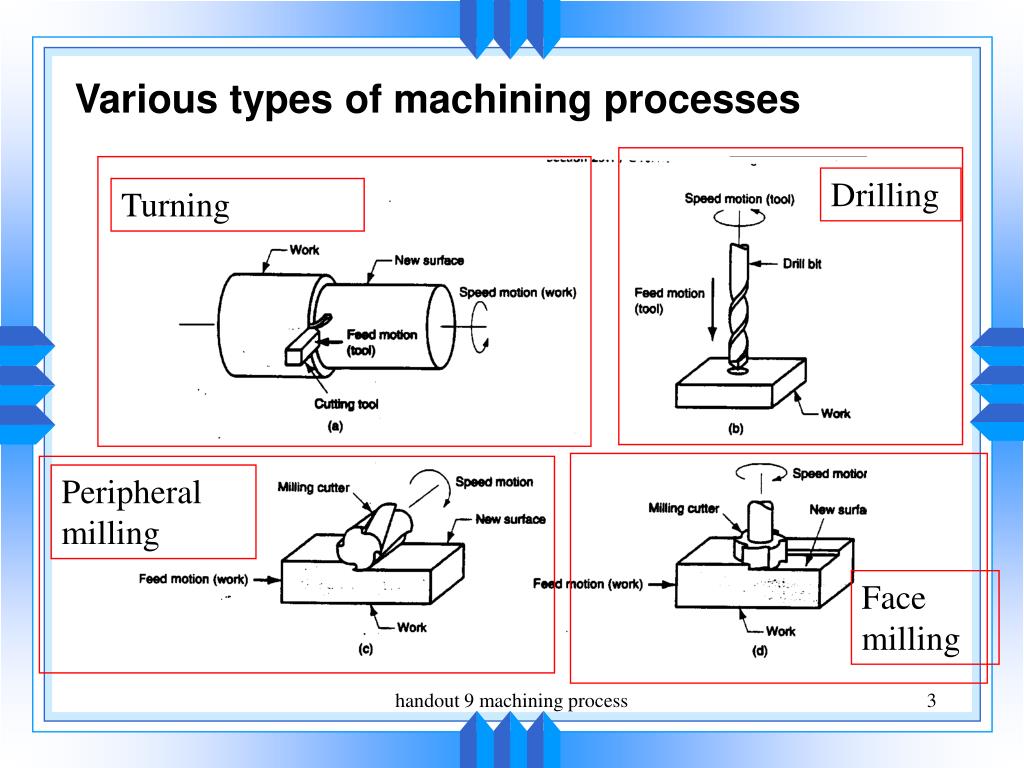

The most precise of all the basic machining techniques are grinding. Hard or soft items are ground to tolerances of plus or minus 0.0001 inch using modern grinding machines (0.0025 millimeters). (1) plain cylindrical, (2) internal cylindrical, (3) centerless, (4) surface, (5) off-hand, (6) special, and (7) abrasive-belt grinding machines are.

PROSES MACHINING PT Ardon Inti Presisi

MACHINING adalah proses pembuatan benda kerja dengan perautan (menghilangkan material yang tidak diinginkan dari benda kerja dalam bentuk chip). Jika benda kerjanya logam maka seringkali dikenal dengan metal cutting atau metal removal. Proses Pembentukan Chip

The best of machining.

Conventional Machining process is a machining process in which the material removal carry out with the traditional method means, not using any advanced method for the machining. Therefore, it is also called as traditional machining process. It uses sharp point cutting tools for the machining purpose, such as the taper tool used in the lathe.

CNC Turning Radius Machining

Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece. This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy.

PPT Fundamentals of Metal cutting and Machining Processes PowerPoint

The CNC Machine Tools and Automation Systems Specialist. Camex Machinery Inc. is a Canadian company specializing in the import and distribution of CNC machine tools and their related accessories and services. Since its foundation in 2009, Camex provides advanced metalworking solutions and comprehensive services for machine shops throughout.