PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation

PPT Welding Symbols PowerPoint Presentation, free download ID391977

So, when to use bevel (groove) in welding? Grooving or beveling is especially used in butt joints that are thicker than 5/8 inches. However, it can also sometimes be used for materials as thin as ¼ inches where it can assist when working with 110-volt welders. But why do you need to bevel your base material?

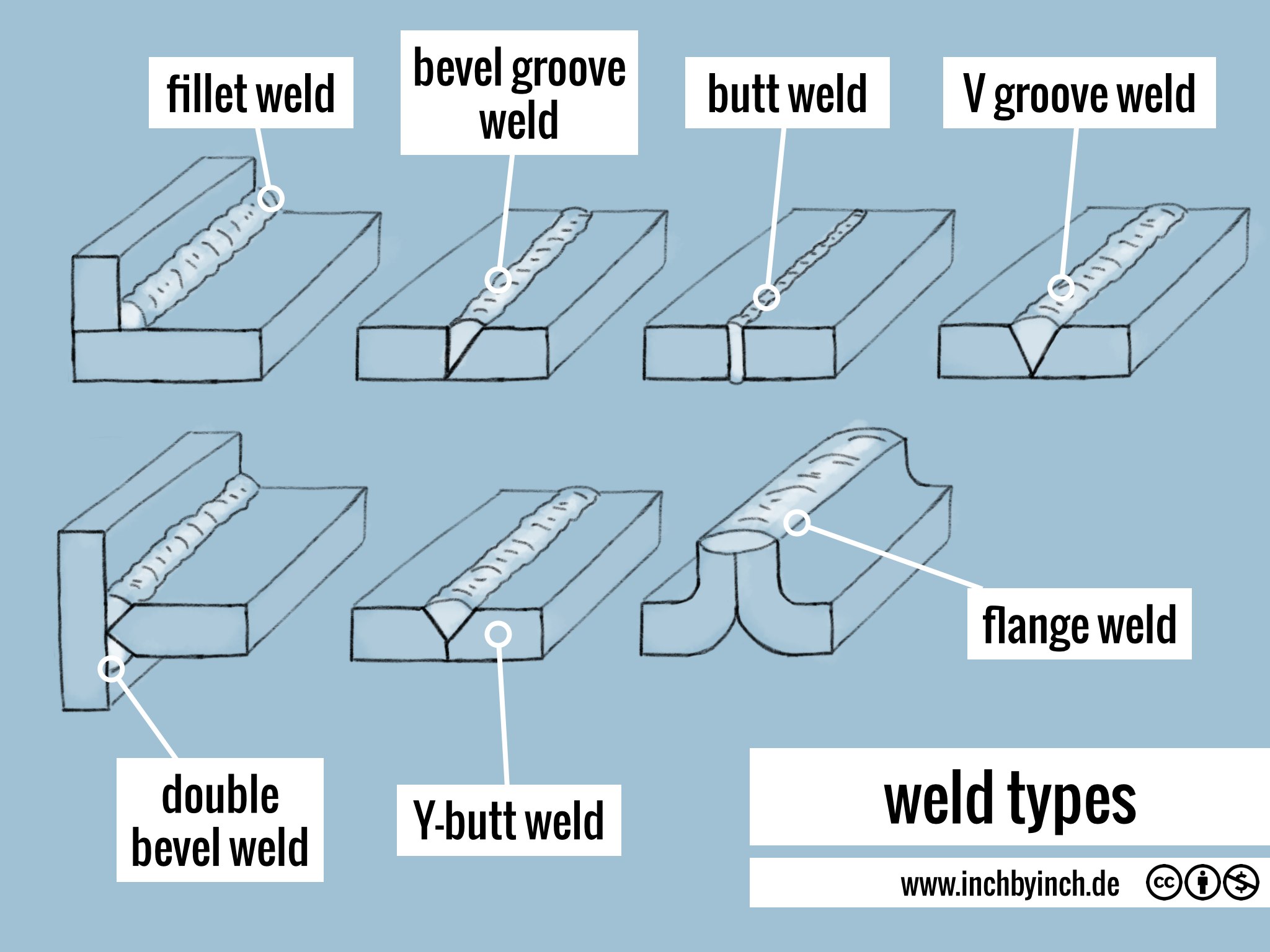

INCH Technical English weld types

What is a Welding Groove? Before we jump to Welding Bevel, let us first know about Groove Welding. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. The purpose of the welding groove is to increase the weld deposit by providing more welding surfaces.

PPT Weld Joint Geometry and Weld Symbols PowerPoint Presentation ID

Watch on In welding, a bevel is an edge preparation presented as an angle. In cases where this type of weld must be made, the welder will make or be presented with a V-shaped groove in the gap between the two pieces of material. The purpose of this groove is to give the welder access to a larger surface area to which the weld can become affixed.

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation

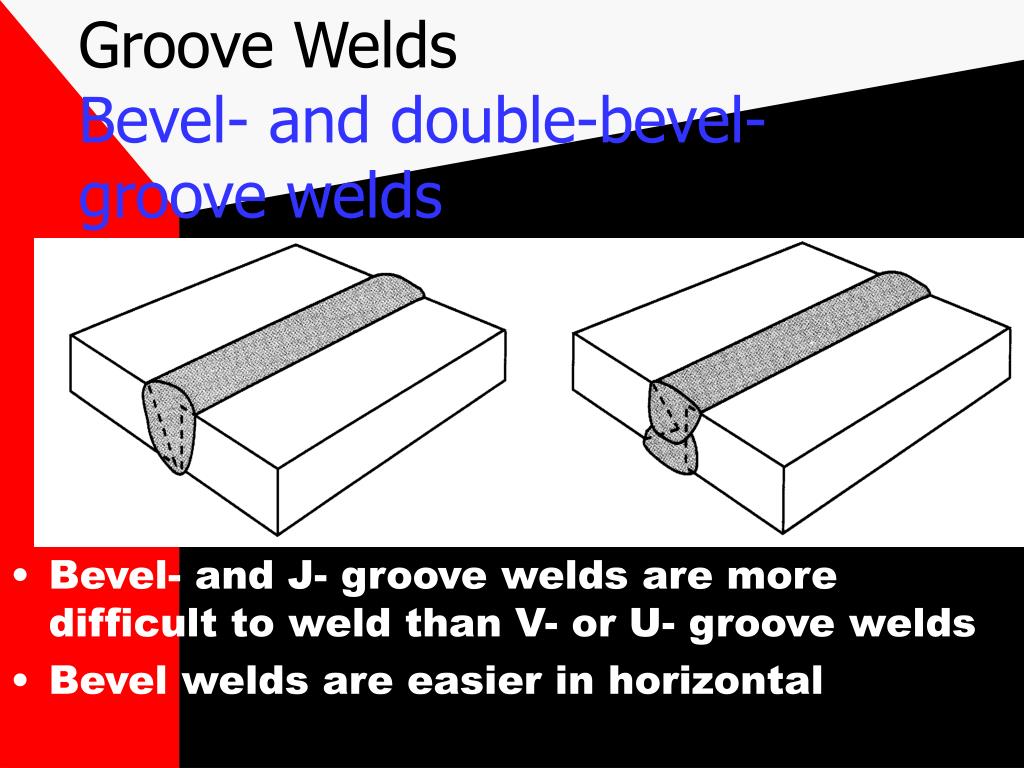

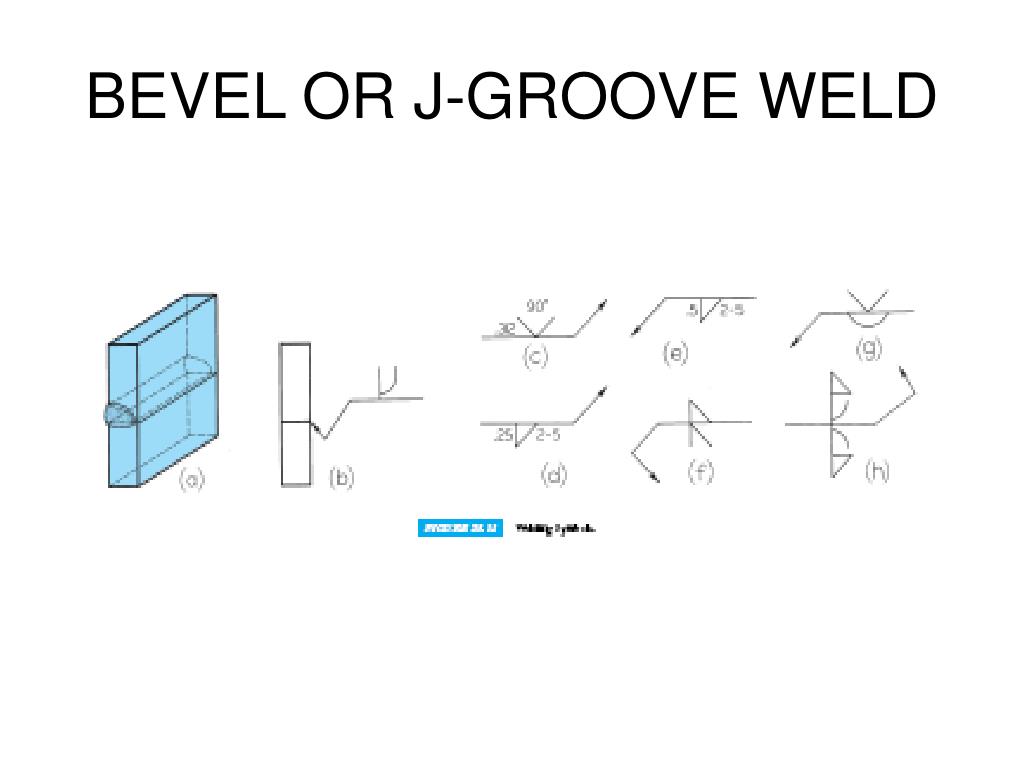

Bevel groove weld is a type of welding in which the edges of the two pieces to be joined are beveled at an angle. What is a bevel weld used for? This type of weld is often used when joining two pieces of metal together at right angles, such as when welding a corner joint.

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation

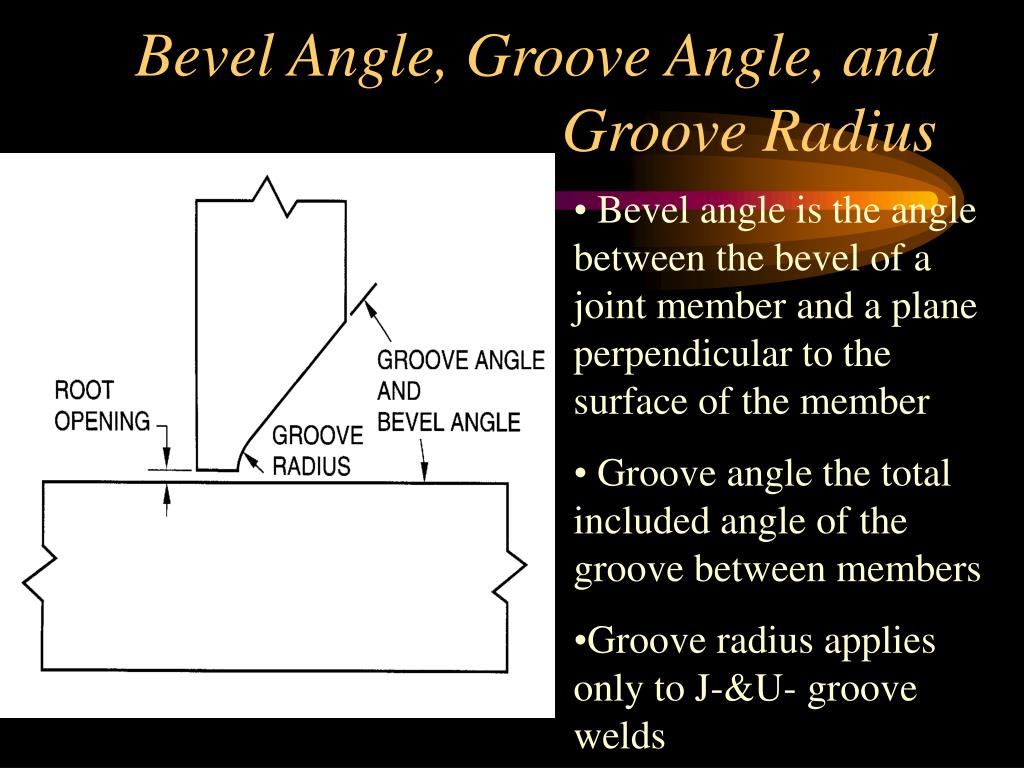

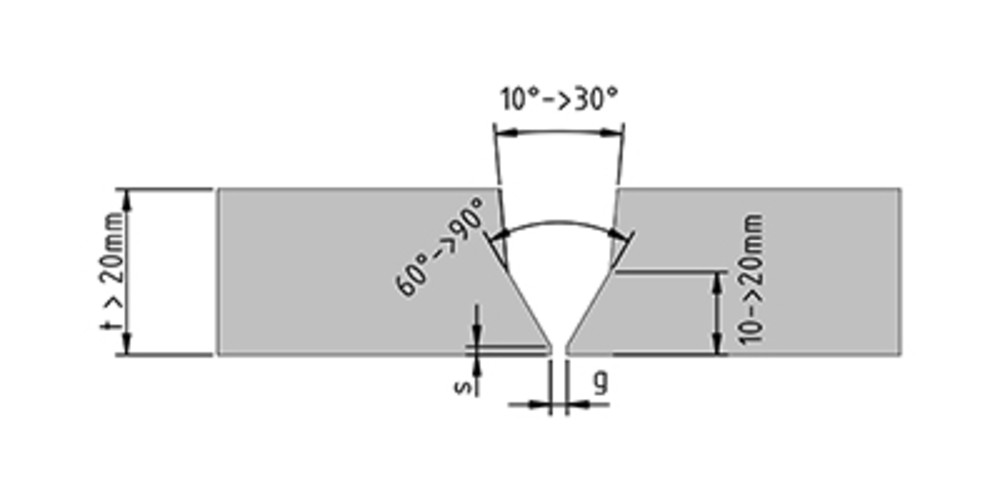

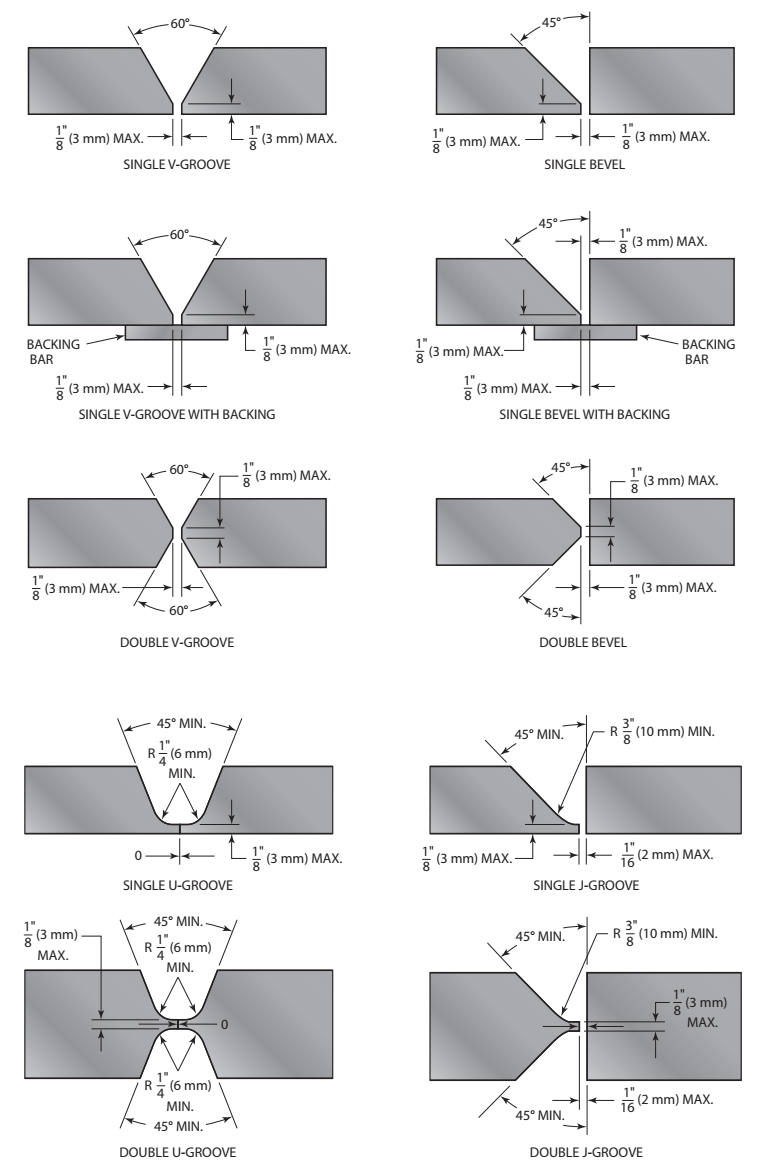

The bevel angle is the angle formed between the prepared edge of a member and a plane perpendicular to the surface of the member.The typical angles for different types of preparations are as follows: V preparation: 25-30 degrees U preparation: 8-12 degrees Single bevel preparation: 40-50 degrees

Single bevel groove joining two W14x176 at a skew r/Welding

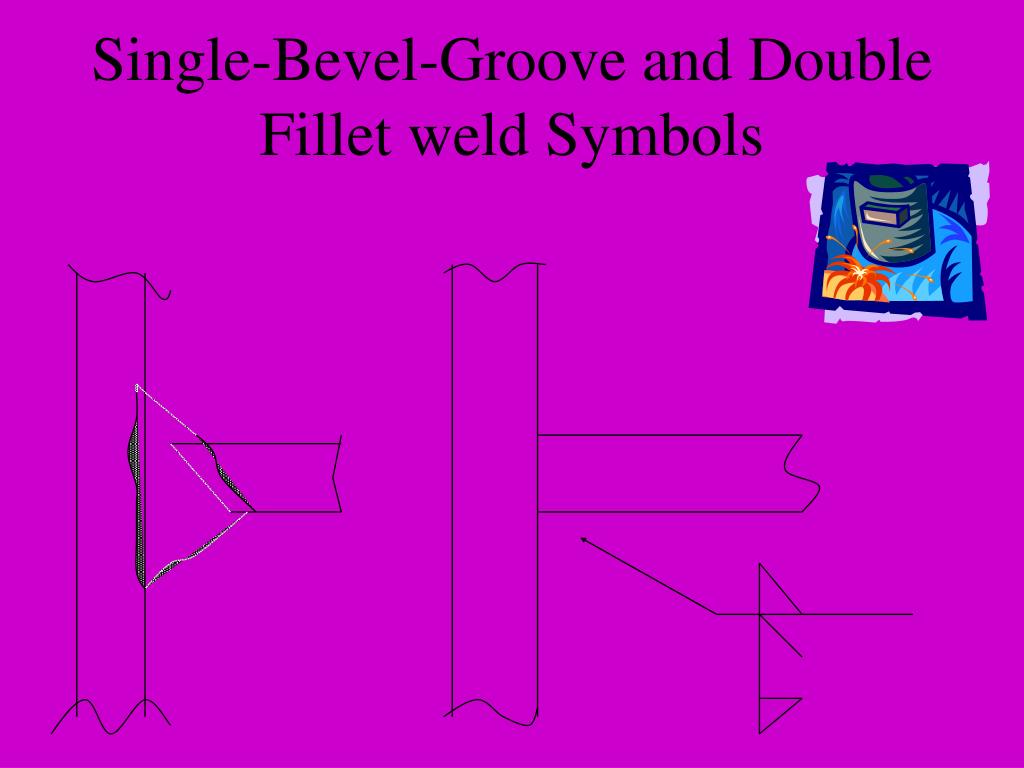

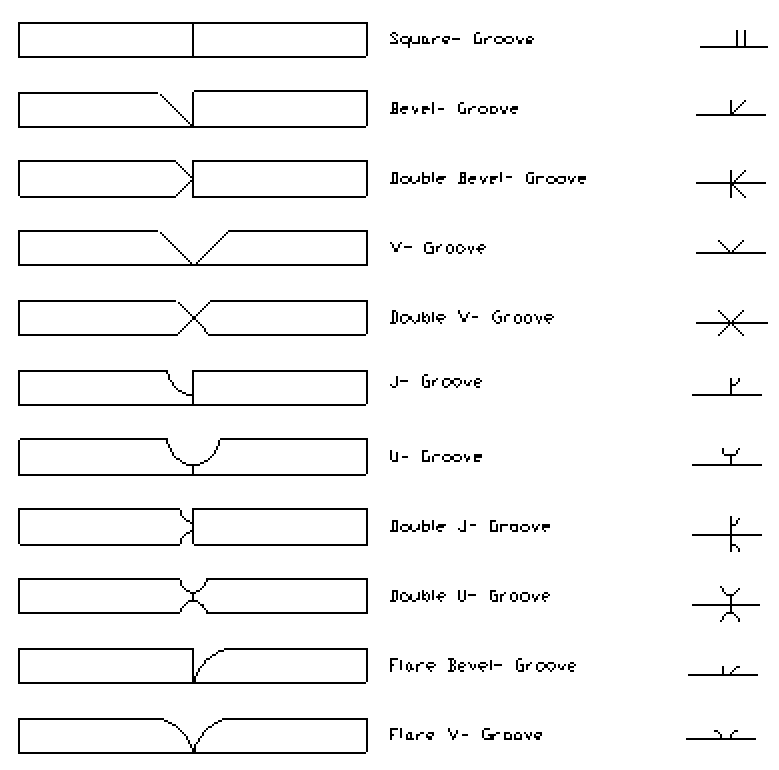

Bevel Groove. When performing a bevel-groove weld, the edge of one of the workpieces is chamfered, with the other left square. The bevel symbol's perpendicular line always is drawn on the left side, regardless of weld orientation. The arrow points toward the piece that is to be chamfered, emphasized by a break in the arrow line (Fig. 5).

AWS Welding Symbols Learn to Draw Welding Symbols for Welding Drawing

Groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. The process of creating the bevels is known as groove machining, and welding the beveled surfaces together is known as groove welding. Full-penetration groove welding

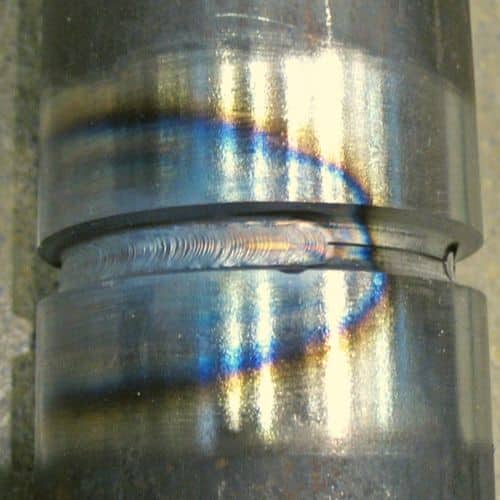

Assembling Pipes by ButtWelding The Different Types of Bevels and How

Groove (Butt) Welds Fillet Welds Plug Welds Slot Welds Stud Welds Spot Welds Seam Welds Surfacing Welds Conclusion Weld Basics What Is a Weld? A weld is used to join parts together by melting the materials and causing fusion. In the GIF above a MIG welder is being used to weld the two metal components together.

PPT Welding Symbols PowerPoint Presentation ID391977

A bevel groove is a type of joint design used in welding that involves preparing only one side of the joining piece with a specific angle before the welding process. While the other side is kept without any weld preparation. This angle is typically between the workpiece surface and a plane perpendicular to the surface, allowing for deeper.

What Is Bevel In Welding And When It Is Used? WeldingMania

A groove is a channel or an opening between two joint members containing the weld metal. You'll make the groove by removing material from the weld joint to a specified size and angle. This guide aims to help you understand bevel and V groove weld symbols and the joint preparations they call for.

What is the design criteria of Bevel Butt Joint? Explain in details

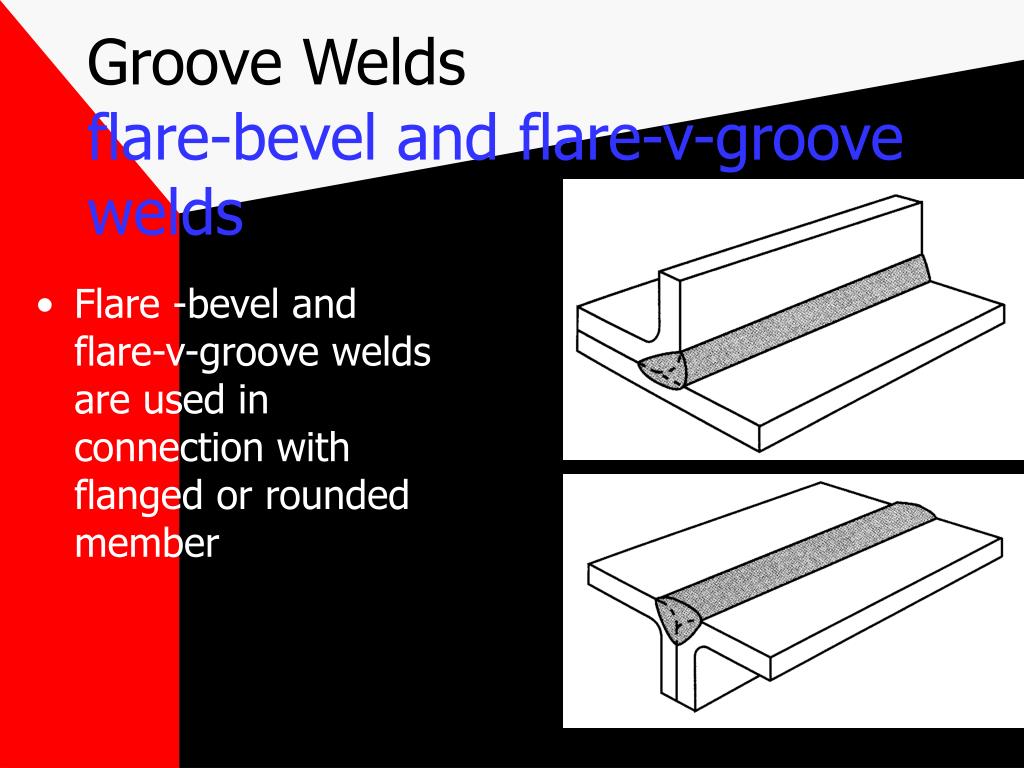

Two Common Types of Flare Bevel Welds: Groove & V. The flare bevel weld commonly occurs in two types. Those are the flare bevel groove and the flare V groove welds. What is a Flare Bevel Groove? The flare bevel groove mostly occurs when you are welding a round, tubular, or curved piece of metal to a flat piece of metal. The curved piece creates.

Welding Bevel Types and Symbols you NEED to know!

2.2.4 Groove Welds. Detail drawings shall clearly indi- cate by welding symbols or sketches the details of groove welded joints and the preparation of material re- quired to make them. Both width and thickness of steel backing shall be detailed. 2.2.4.1 Symbols.

Demand Products 1 1/2 X 3/4 X 1 BEVEL GROOVE. GBB154

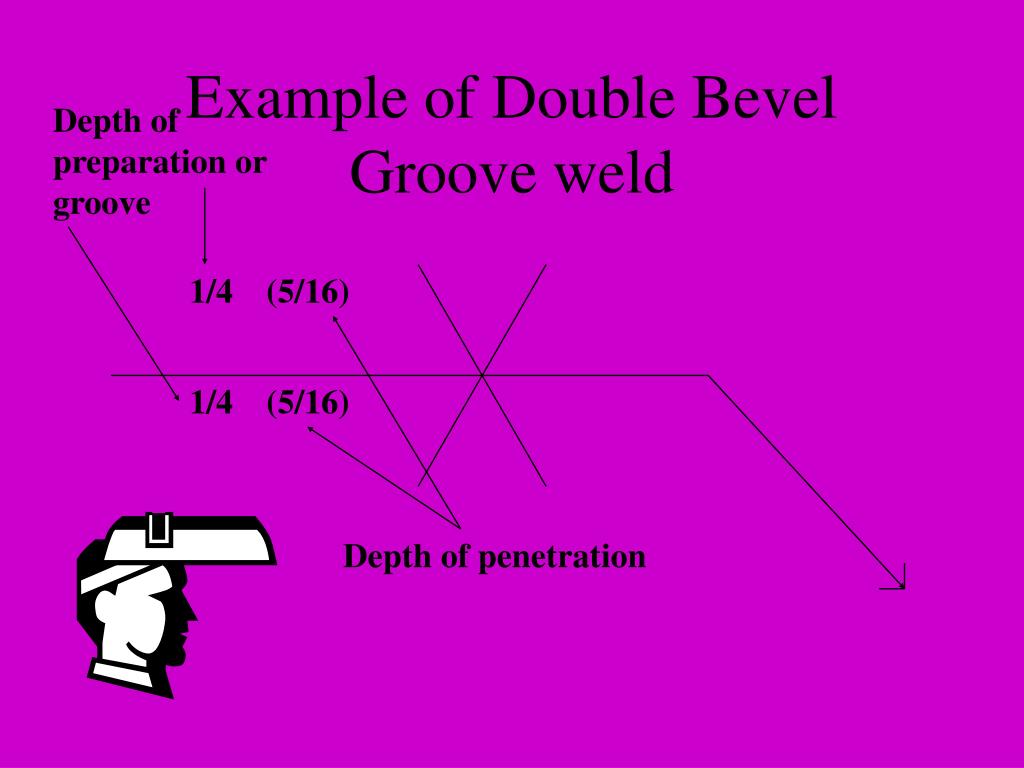

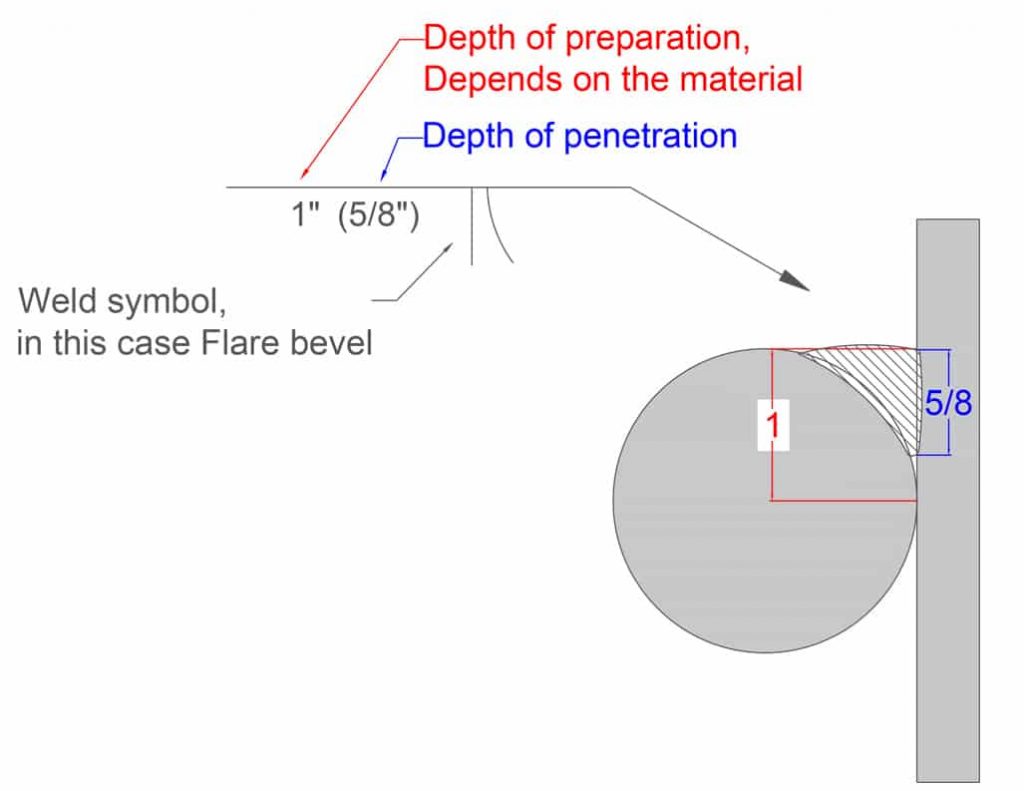

A bevel angle exists when only one of the workpieces is angled, as in a single bevel weld. The depth of the groove is represented by D, in Figure 5. The effective throat, T is indicated in parenthesis in the weld symbol. This element is only shown when the weld is not to be full penetration and represents the desired penetration depth of the weld.

Welding Symbols ISO 2553 and Weld Joint Design

Bevel angle is only one half of a V groove. This dimension is shown within the weld symbol itself. There is a possibility for two different angles if you are applying to a double groove weld. The arrow and other side do not have to necessarily match in angles. A groove weld is the most common weld to have a root opening.

Welding Symbols Types, Example Diagrams, Free PDF Charts

What is Single Flare-Bevel-Groove Weld? In a Single Flare Bevel Groove Weld joint configuration, a round member (Pipe/ round bar) having a curved surface is rested on a flat surface.The Flare weld is obtained by welding lengthwise to one side of the weld joint. Refer below figure, top left for an example of Single Flare Bevel Groove Weld.

PPT CHAPTER 25 PowerPoint Presentation, free download ID969154

A bevel weld is a type of weld joint that is commonly used in various industries, including construction, manufacturing, and fabrication. It is a technique where the edges of two metal pieces are shaped in a way that creates a V or U-shaped groove.This groove allows for better penetration of the weld, resulting in a stronger and more durable joint.Bevel welds are often used in applications.